Hmm, I was hopeful until I read this page..

http://www.bgsoflex.com/mjl/mjl_edis_summary.html

this is the worrying bit.. "Note that the SAW pulse must be synchronized with the PIP negative-transitioning pulse - it cannot be applied asynchronously to the PIP signal, otherwise incorrect advance commands will be interpreted by the EDIS". This is the first page I have read that says the timing relationship between PIP and SAW has to be tight.

It still *might* be possible in a different way.

According to that page, The Megajolt must respond to the PIP signal from the EDIS fairly quickly with a SAW (Advance) pulse.

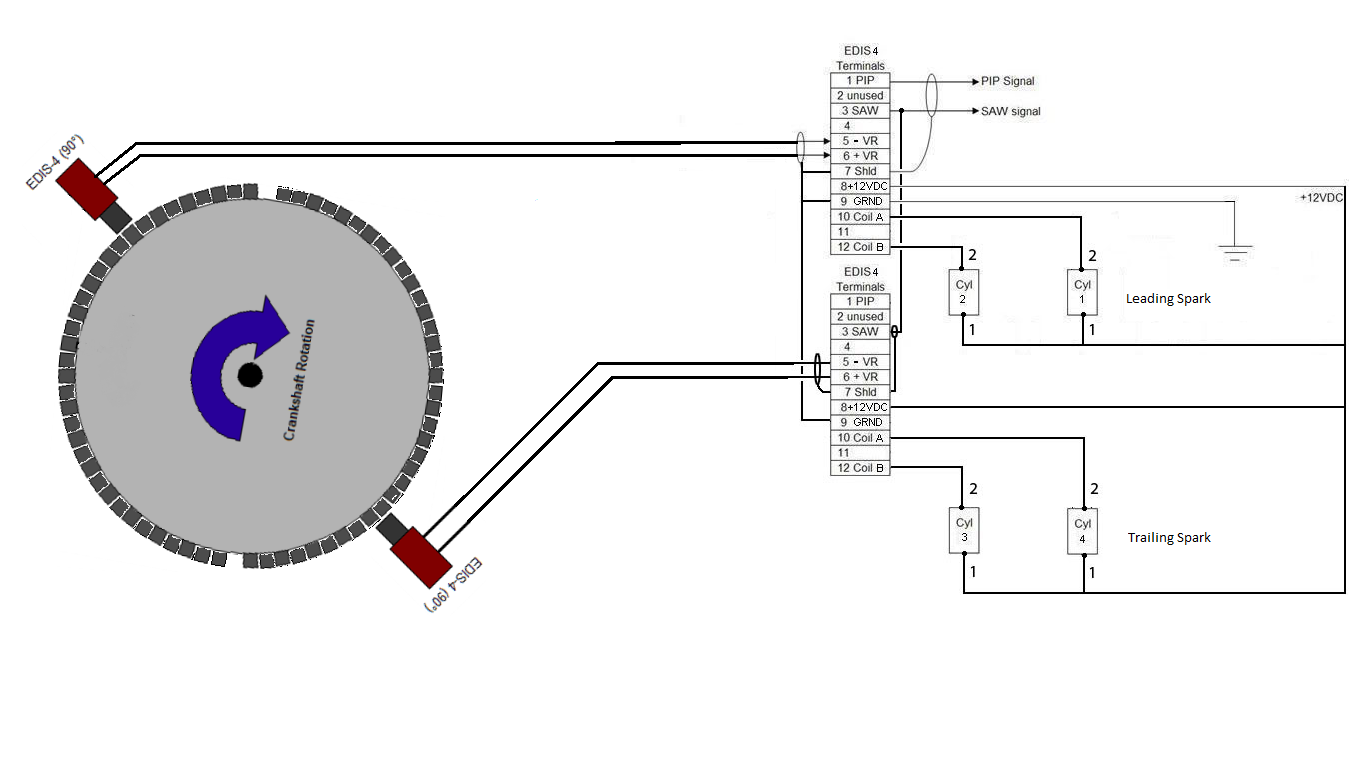

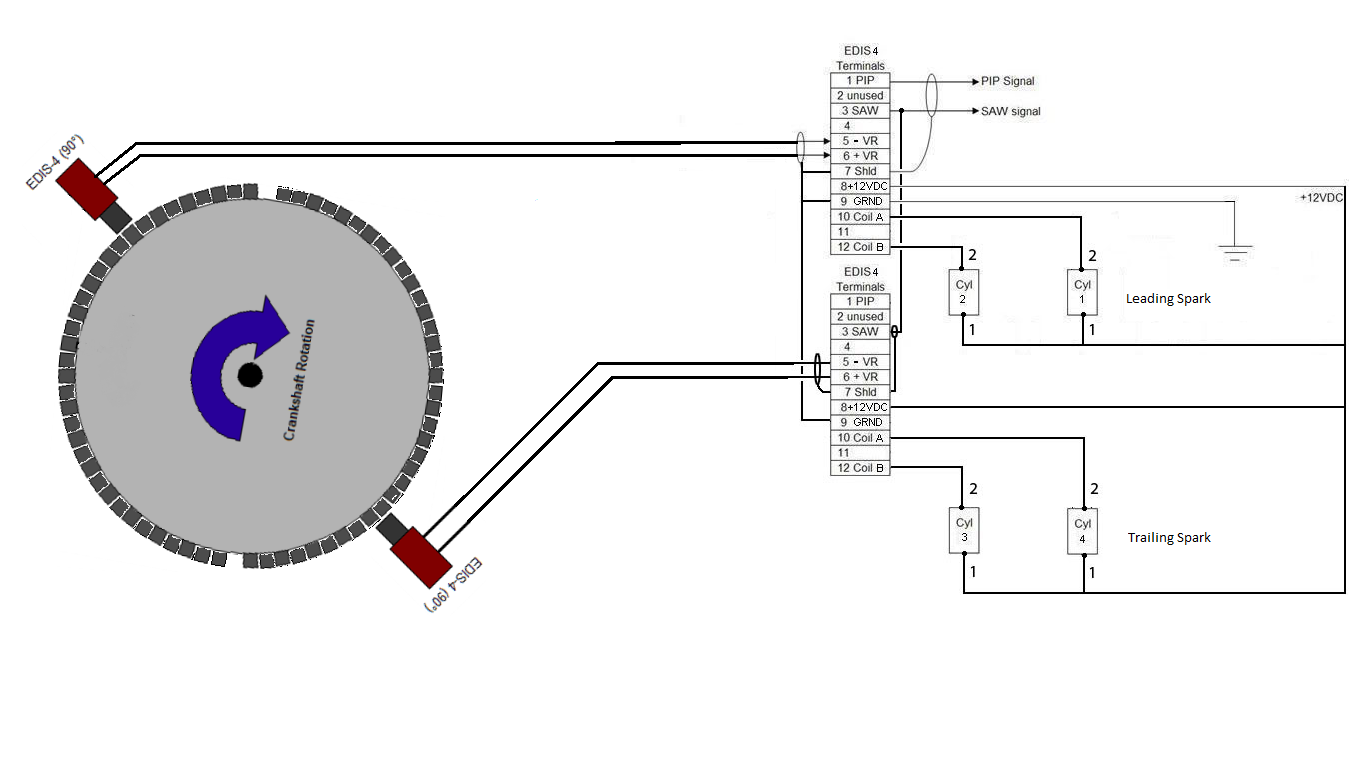

Depending on how the MJ determines the RPM from the PIP signal timing, it might be able to cope with *two* PIP signals (one from each EDIS) and respond to each PIP signal with an individual correctly timed SAW response..

(RPM is a slippery concept in a rotary anyway, with their offset gear driven crankshaft

)

But, it all depends on whether the MJ is figuring out the RPM by timing the *length* of the high side of the PIP pulse, or whether it is timing it by measuring the interval *between* PIP pulses.

If its the former, it might still work, if its the latter, then it wont.

If the MJ measures the length of the high side of the pip pulse to determine rpm, and then responds with a timed saw pulse (based on the map), and thats all, then it shouldnt care if another PIP pulse comes along a few degrees later wanting another SAW response.. provided the second PIP pulse (from the trailing EDIS) doesnt arrive while the SAW pulse is still being sent for the previous PIP pulse..

referring to that page, it looks like the maximum length of the SAW pulse is ~1500 microseconds or 1.5 milliseconds.

Now this is where my fuzzy rotary knowledge could trip me up, so I'll do some calculations based on a piston engine and you can see if you can adapt them to rotary-ignitions.

Lets say a 6 cylinder engine doing 7000 RPM (close to the EDIS's maximum - hmm, more on that in a moment).

7000rpm = 116.6 Revs per second. about 8ms (.008 seconds) for each revolution (pretty damn quick !)

Half the cylinders fire each Revolution, so thats 3 cylinders firing within that 8ms, or about 2.8ms between firing events. oh oh, that doesnt sound good.

if we have to fit a SAW response pulse that could be up to 1.5ms in length in between PIPs that could be a mere 2.8ms apart, I think we're in trouble as far as getting two responses in there at high RPM..

This could explain the EDIS's 7000-8000rpm Limit, since somewhere around there the PIP signals are going to start coming faster than the time needed for the SAW response to be sent, although it is an inverse relationship timing signal (the more advance required, the shorter the SAW reponse pulse length.. at 40 degrees advance, SAW is only 500ms (or 0.5ms) long, so that would help keep the from crashing into each other).

But, at say 7000pm, that 2.8ms spacing = 120 degrees of crank revolutions (6cyl = 3 sparks per rev).

if you have two EDIS's connected to one MJ, and the second EDIS sends a PIP signal just 10 degrees later than the first one (instead of 120 degrees later) , then the 2nd PIP signal is going to appear .0002s (200us) after the first. crash.. the second PIP probably just ran over the time that the SAW response to the first PIP is taking, and things are likely to get messy with unpredictable timing on the second EDIS. Even if the second PIP signal didnt confuse the MJ at that point. Bugger.

Additionally, before you go and crunch the numbers for a rotarys timing, it just occurred to me that, that is an EDIS even going to handle the maximum RPM of a Rotary ?

I measured two EDIS-6's a while ago and found they stop sparking somewhere around 7000-8000rpm.. (I forget the exact values, its in a previous post of mine if you want to find it).

I just checked and found that the rotors turn at 1/3 of the output shaft speed, but of course, there are 3 sides to the rotor, so it sounds like you still need 3 sparks per output shaft rev, so 10,000rpm = 10,000 6 cyl rpm as far as the ignition is concerned, even if the rotors are only doing 3300rpm at 10,000rpm shaft speed.

So, what do you typically spin your rotaries up to ? If you're going much past 7000rpm, youre going to pushing the limits of the EDIS module anyway, so whether the MJ can handle it might be a moot point.

Phew, that all sounds rather messy, I hope I'm not making you more confused with all this.