The car ran on the base map but on idle and in low revs it gives me back fires. so I want to create my own map from the factory specs but I got stuck with the numbers. I used the xsl from this site to help me convert some numbers but still no real luck.

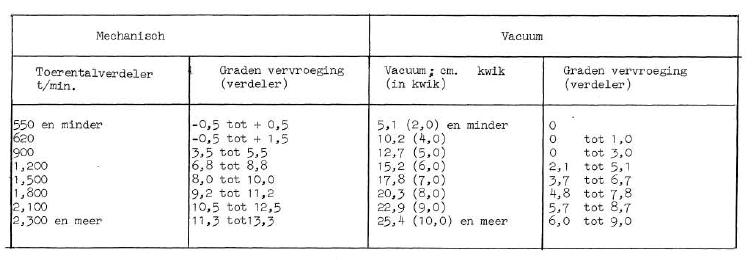

I made a screenshot from the factory specs it is in dutch but pretty self explaining.

1st colomn is RPM

2nd colomn is advance in degrees

3rd colomn is vac in cm and inches between ()

4th colomn is advance in degrees

The first thing that gives me problems is the RPM. If this is crankshaft rpm I need to multiply by 4. That means up to 9200 rpm but the specs tell me max 6000, so that can't be correct but 550 rpm isn't nearly enough to let it idle.

the second is the inHG /cmHG when I use the calculator in the xsl sheet the lowest load value (ABS:MJLJ) I get is 68 while on most maps it starts at 0.

third I only got 8 value's from the factory spec list and I need 10. Where do you add numbers. I searched for the biggest gaps between value's and added a value in between. But does that mean if you add a value in the RPM between value 7 and 8 you also need to do this for Load between 7 and 8 or can that be between 4 and 5 for example?

Hope somebody can point me in the correct direction.