I'm converting it to Megajolt this winter during snow (& salt) season.

I've tried to be exhaustive with my presentation.

Only big advice I've got: Get good crimping tools! You must invest in one pair of pliers at least. I've got 3: one for moley pins, 2 for regular flat pins.

I would discourage anybody who would intent this process with regular pliers.

There’re a lot of stuffs made on the engine:

- Head milled, ported, polished, unshrouded, combustion chambers CC’ed, new valve seats, Dual lub systems (internal in cam + spray bar)

- Cam with asymmetrical profile from Rebello Racing with adequate springs, rockers, etc.

- Bottom end is new also with new pistons, rings, bearings, etc. Compression ratio is around 9.0:1 / 9.5:1.

- 3x Weber 40DCOE with ported intake. Each runner is linked with the others with a canal to balance pressure between them.

- 6-2-1 exhaust header + 2,5” exhaust

- Soon to disappear Mallory Unilite distributor

I’m in process of converting the car. Wiring is almost done, I now need to focus on mechanical installation.

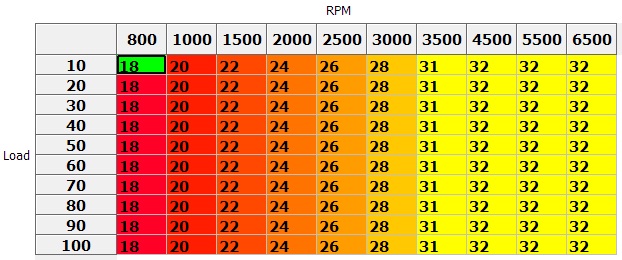

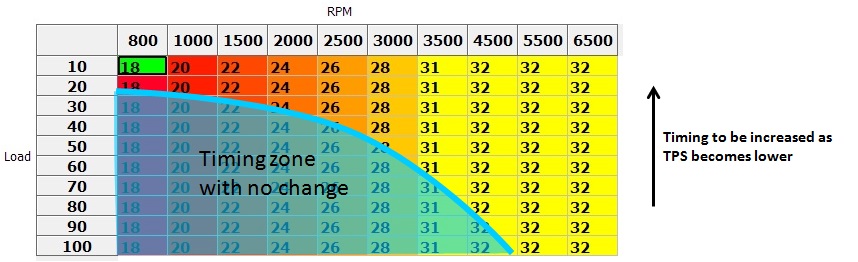

I’ve chosen to run MJLJ with TPS option but I don’t exclude to convert it to MAP later.

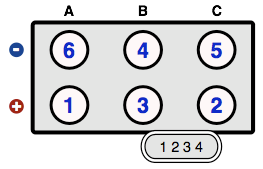

For TPS, I’ve picked one up from a BMW 323ti (E36). The TPS is not having any spring loaded control, its shape for the shaft is easy to reproduce (a round ø8mm shape with one flat) & it is easy to get at any junkyard. Only concern would be that it is not water tight. I got it in Europe for 15€ with the entire throttle body (people get rid of it for better 325i unit)

I also got the one from Autosportlabs webshop but it is big, spring loaded with complex shaft print, so I won’t use it after all.

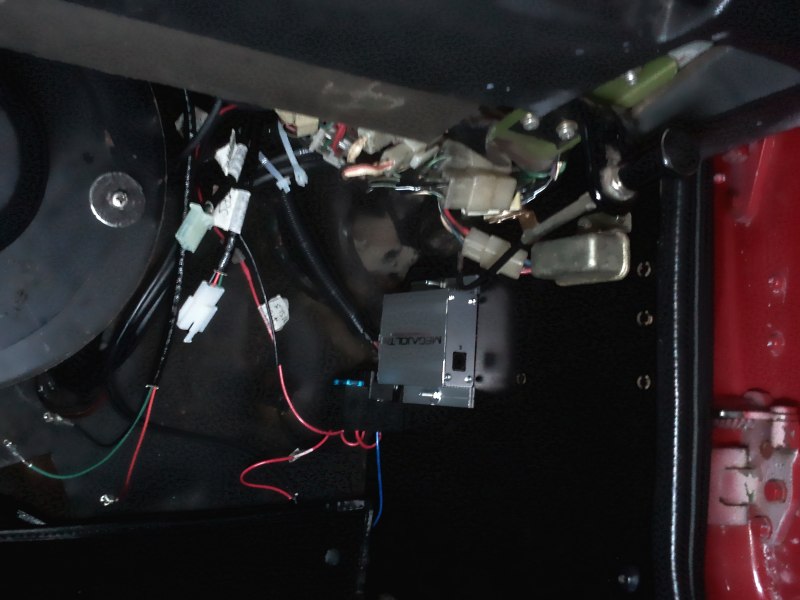

Regarding install, I’ve installed MJLJ box on the sidekick panel on passenger side with a relay support + fuses.

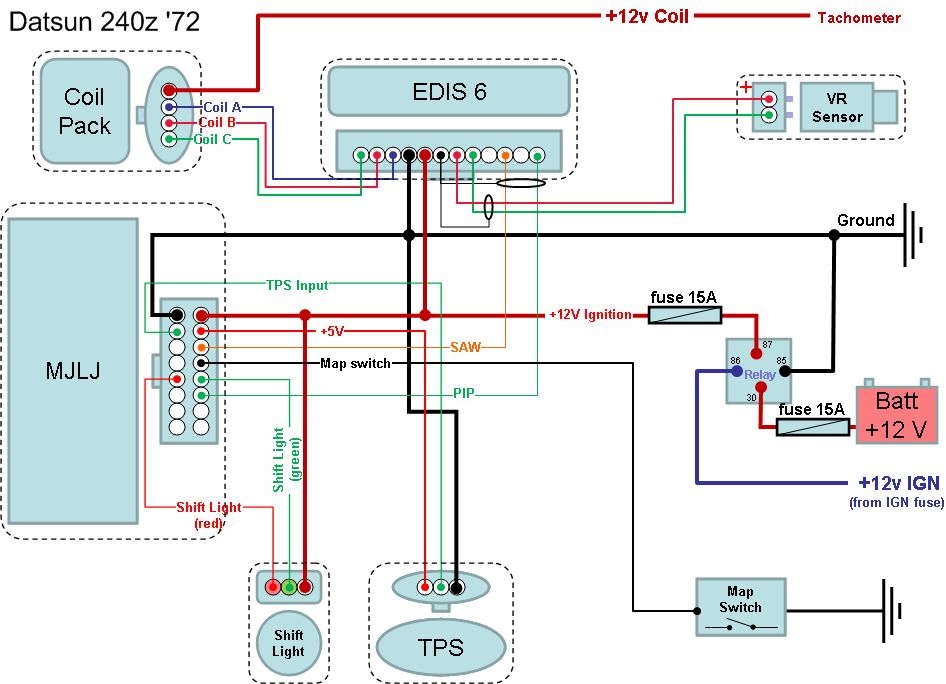

I’ve made a wiring diagram based on info from the “how to” section. Only difference is the way I expect to power up the EDIS coils. I’m going to plug the +12V source from the coil + side since my tach is triggered this way.

All wires are crimped with proper tools. When wires needed to be connected together; I’ve twisted them together, soldered them & protected them with shrink tubes.

Wires are all protected with high temp hoses under the hood.

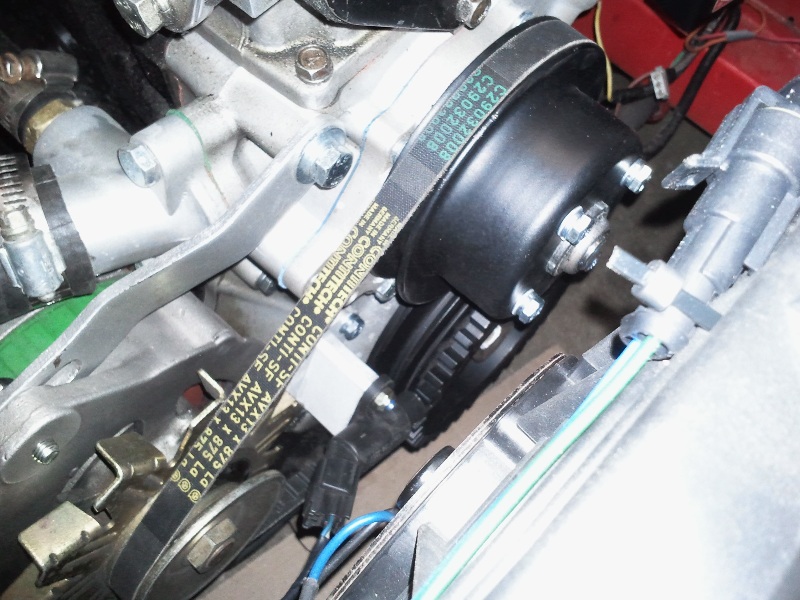

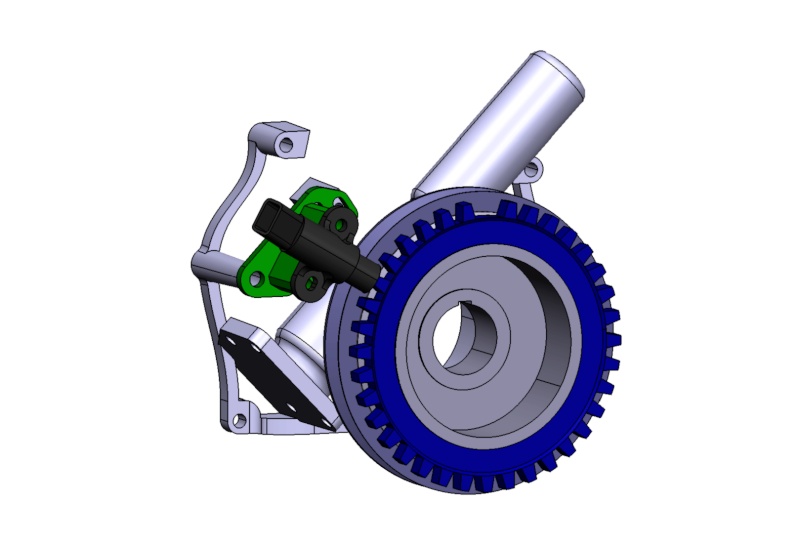

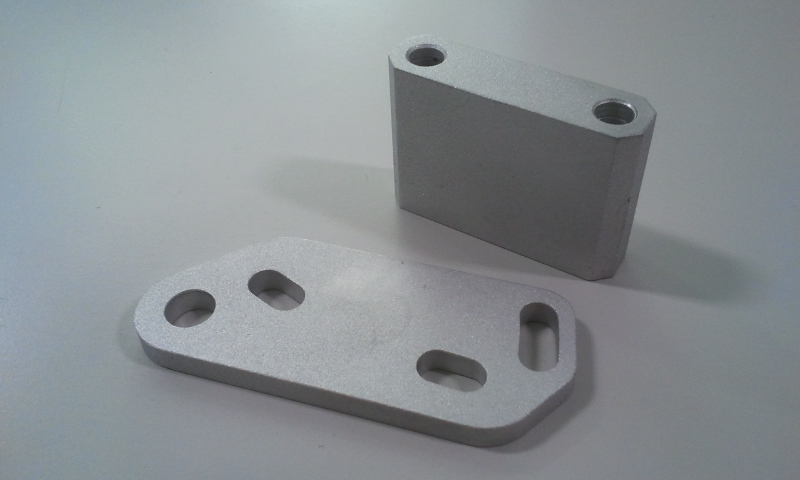

For VR sensor, I’ve made a CAD model of the front of the engine to design a support. Support, in aluminum, is made with a CNC machine. I’ve taken into consideration some margin for adjustability.

The drawback from the support is I need to ditch the stock fan & go with e-fan instead. I wanted to do it anyway so I did not bother…

36-1 wheel is coming from the EDIS car donor. Crank damper has been machined to be slightly smaller than the wheel. I cannot feel any play but wheel can rotate freely around the pulley.

The plan is to install the VR sensor, get the wheel in front of it accordingly, get a mark done & spot weld the wheel in place (hopefully the weld will not hurt the rubber, I’ll be careful about that).

EDIS coils have some rubber pads installed to avoid vibrations. Pads also raise the coils allowing me to get it install on a flat surface without any specific support. Pads are male/male type with ø20 OD. I had to make a thread on each Coil support hole to make pads fit.

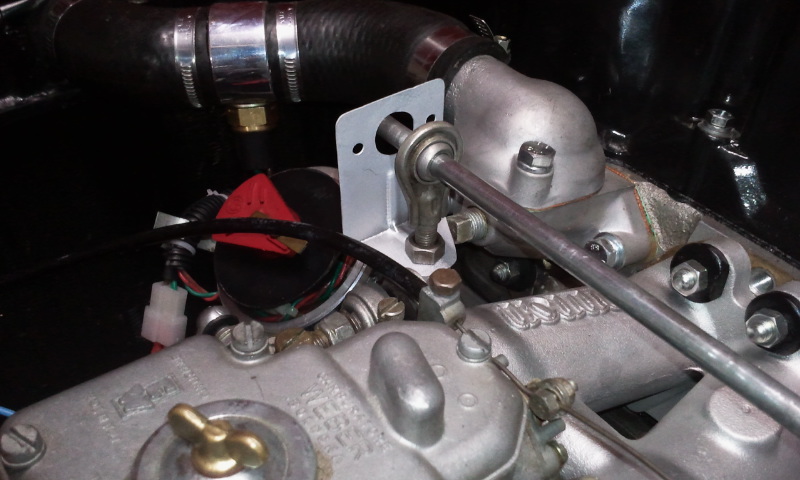

TPS will be mounted on carbs rod linkage instead on carb shaft. My DCOE are the old style, there’s no hole on housing to install easily a support for TPS.

Drawback with the way I expect to install TPS is that I won’t have 90° angle between idle & WOT but around 45-60°. Hopefully TPS resolution / sensitivity will be sufficient.

The support will be a very simple steel plate design bent, nothing really fancy. Still need to design it and make it.

To finish the first post, here's how my install looks like for now (or almost, wires have been setup, I don't see anything anymore from the driver side)

The next steps would be to try the new support, check 36-1 wheel position, get the wiring finished under the hood and install EDIS components.