I had a muck about with your image, Brent, and came up with this option (don't want to tread on any toes though

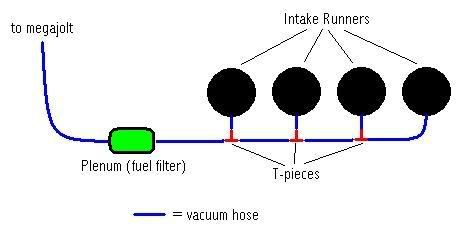

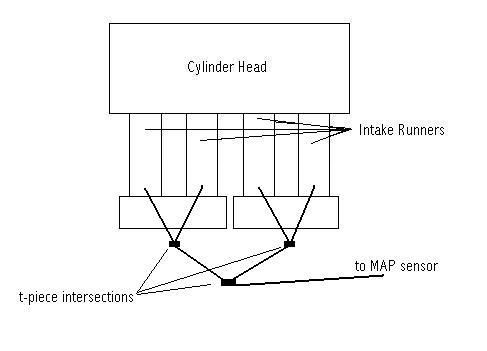

). Would this offer any advantage over the other arrangement? The reservoir would have a union per runner, and basically replaces the tee-pieces. If this format was employed it'd most probably be easiest to mount it locally.

As for the filling and emptying, on an NA car such as a twin-SU'd Mini, from the moment the engine cranks the reservoir would see negative pressure, and this vacuum would only vary, rather than fill and empty and at worst would take split-seconds to catch up. Provided the reservoir is not overly large, there'd be no problem at all - between 1/4 and 1/3 of engine capacity would be perfect.