My TPS sensor is plugged on carbs linkage, wires are running close to heat shield which is sharp, exhaust headers that are running hot, etc.

This is a very hostile area that could lead to failure. Same goes for MAP that can go bad: punctured hose, defective sensor, power going bad, etc.

Of course, I've managed to protect my wires the best I could. They are inside a thermal resistant hose, some clamps hold wire harness tight to avoid movements/vibrations, etc.

Still, I was looking at how to set up ignition map for bad event.

2 solutions come to me:

- Secondary map with switch with no load input effect. If something bad happens (including switch itself), safe map would be enabled.

- 0 load raw needs to be set conservatively. A new raw with low load needs also to be created to get back to "normal" with very low load (2% TPS in my case).

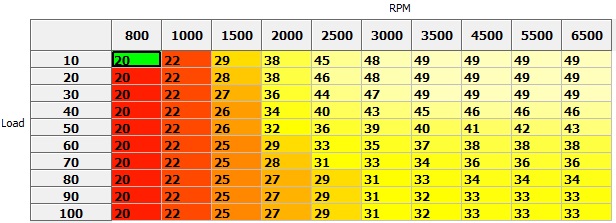

Here's an example of current running map on my setup and the one modified with low timing with 0 load (sensor inactive)

and modified map with safe timing at 0 load.

Issue with this solution is that I'm losing 2 raws of resolution in my map to create such feature. So 0 & 2% load have been created, 90% & 100% TPS load are gone.

What do you think about it?

Is there any simpler solution?

I haven't tested this map yet, so I don't know either if it would make a difference during decelerations since this is the only state where those new timings could affect my setup.